A ONE INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to A ONE INDUSTRIES

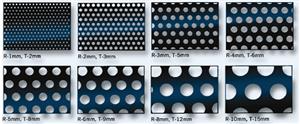

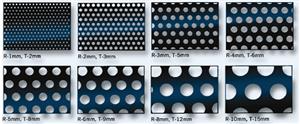

Perforated Sheet

Perforated sheets can be used to benefit in many situations, e.g noise and weight reduction, air control, filtration, as a decorative finish or simply for anti-skid flooring. The varied qualities offered by perforated sheets make them ideal for sorting, facades, ceilings, lamps, shelves, shielding, stairs and many other applications, far too many to mention!

AVAILABILITY OF TOOLING

We have Number of different patterns available and ready for production. However, if we do not have tooling for the exact pattern you require, our modern and well equipped tooling department is able to produce cost effective tooling, enabling us to supply perforated products exactly to your request.

You can also refer to our large program of perforated sheets held in stock or be inspired by our pattern catalogue.

As the world's largest manufacturer and supplier of perforated products we are the only partner you need!

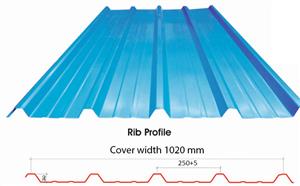

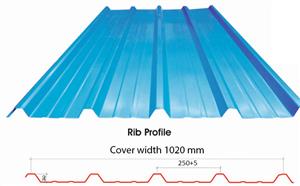

Standng Seam Roof

Gee Aar Seam Roof is new generation seam roof system designed in 485mm panel width/chest ht of 51 mm. Roof panel is sealed by an electric remote control seaming machine which ensure perfect weather tightness to the roof. The roof floats on a system of sliding clips that prevent damage from thermal expansion and contraction . This system is most reliable roof system for large span buildings.

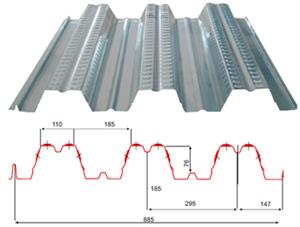

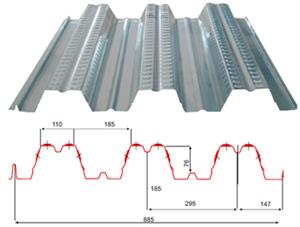

Steel Emboss Decking Sheet

Special emboss marks rolled into the profile creating the highest bond between concrete and steel floor

Material : 76 mm Decks are manufactured from test quality of CR Coils as per IS:513 apart from these material, 76mm sections can be rolled from galvanized steel, Pre colour coated and bare galvaume sheets. 76mm Sections are manufactured in thickness of 0.5mm, 0.6mm, 0.63mm, 0.8mm, 1.00mm, 1.25mm and are available in any standard lengths as per customers requirement subject to transport restrictions (upto maximum of 12mtrs length)

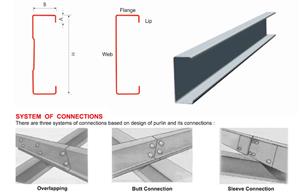

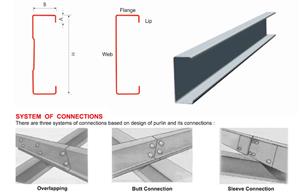

Cee Purlins

Cee Purlins are structural members designed and produced using the advanced technology, quality and customer oriented services, for use as secondary supports for economical roof sheeting and wall cladding systems in any type of building with following added advantages :-

1. Continuous splay or splicing for better structural strength.

2. 45° Lip for better sectional modulus and easy nesting.

3. Supplied in required length with pre-punched holes for quick bolting.

4. The system gives an excellent strength to weight ratio with flexibility for specific size requirement.

5. More than 40% saving in steel and more than 30% saving in overall consumption cost.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.